Conversion to PCR material

Plastic can't be sustainable? It can - if it remains in the cycle and is recycled.

We are taking our sustainability efforts a decisive step further: After two years of intensive project work, we are now switching almost our entire household range to sustainable PCR material!

Conversion to PCR material

What is PCR material?

PCR stands for Post-Consumer Recycled. These are plastics that were already in circulation or used - for example packaging, foils or containers - and are collected, sorted and recycled after use. The material is shredded, washed, dried, regranulated and homogenised to produce a high-quality, reusable plastic. In this way, what is supposed to be waste is given a second life (circular economy).

Why the switch to PCR material?

Plastic consumption in Switzerland is rising steadily: foils, bottles, pots, canisters, pipes, buckets - the result is a huge amount of waste. Around 80 % of plastics are still simply incinerated. We want to counteract this trend.

We are convinced: Plastics are not waste, but valuable materials that deserve a second chance. Especially for brushes, plastics are particularly suitable because they are robust and durable – ideal for use in wet areas. This is why PCR material is the perfect solution for us: We can maintain the functionality of our products and at the same time make an important contribution to circular economy. In product development, we aim to develop mono-material solutions that can be easily integrated into closed material cycles in the future.

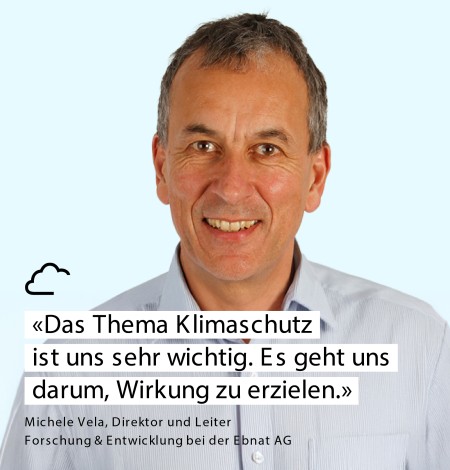

The transparent origin of our raw materials enables us to report precise environmental indicators. The PCR material used impresses with a significantly lower CO₂e value compared to new materials. The significantly reduced energy requirement in production is particularly significant - a clear advantage for the environment and climate.

Conversion to PCR material

Where does our PCR material come from?

Regionality and short transport routes have always been important to us - they fit in perfectly with our sustainability standards. We are therefore particularly pleased to have found a partner in Eastern Switzerland for our PCR material.

This means: We only use material that was already in circulation in Switzerland. Using state-of-the-art technology, polypropylene materials delivered in sorted batches are processed and reused in a new form. Short-lived disposable catering packaging is turned into long-lasting quality products - like our brushes.

Conversion to PCR material

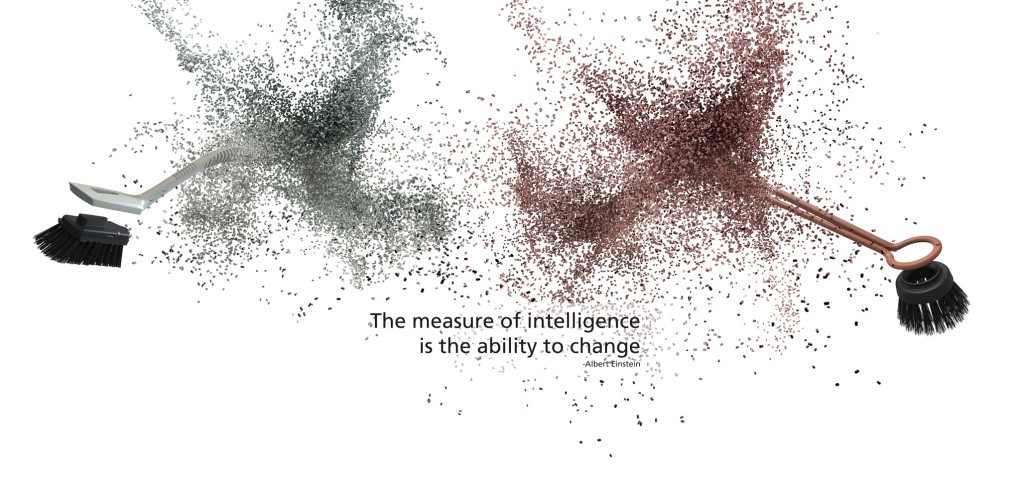

A New Look

The change in material is also accompanied by a visual change: In future, our range will be produced in timeless grey tones. A modern, discreet design that should suit the taste of most customers - and also makes our sustainable reorientation visually visible - in line with the motto "grey is the new green".

There are few products that we cannot convert to PCR material. This is mainly due to the colour and material properties:

White products - such as toilet brushes, which are expressly preferred in white by many customers - are difficult to produce in the desired colour purity using PCR material. We therefore continue to manufacture these items from new material.

Transparent products – such as items made of polyester – will also remain unchanged, as they are made of a different material.