Login +41 71 992 62 62

COMPANY HISTORY

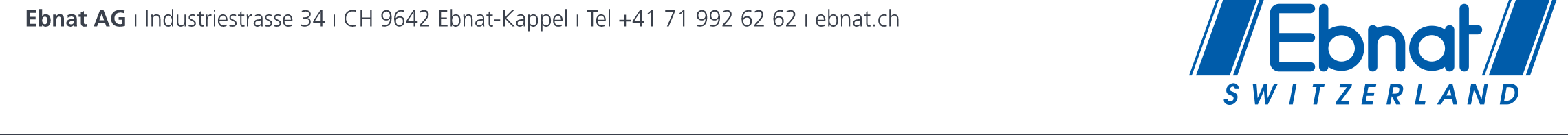

1914

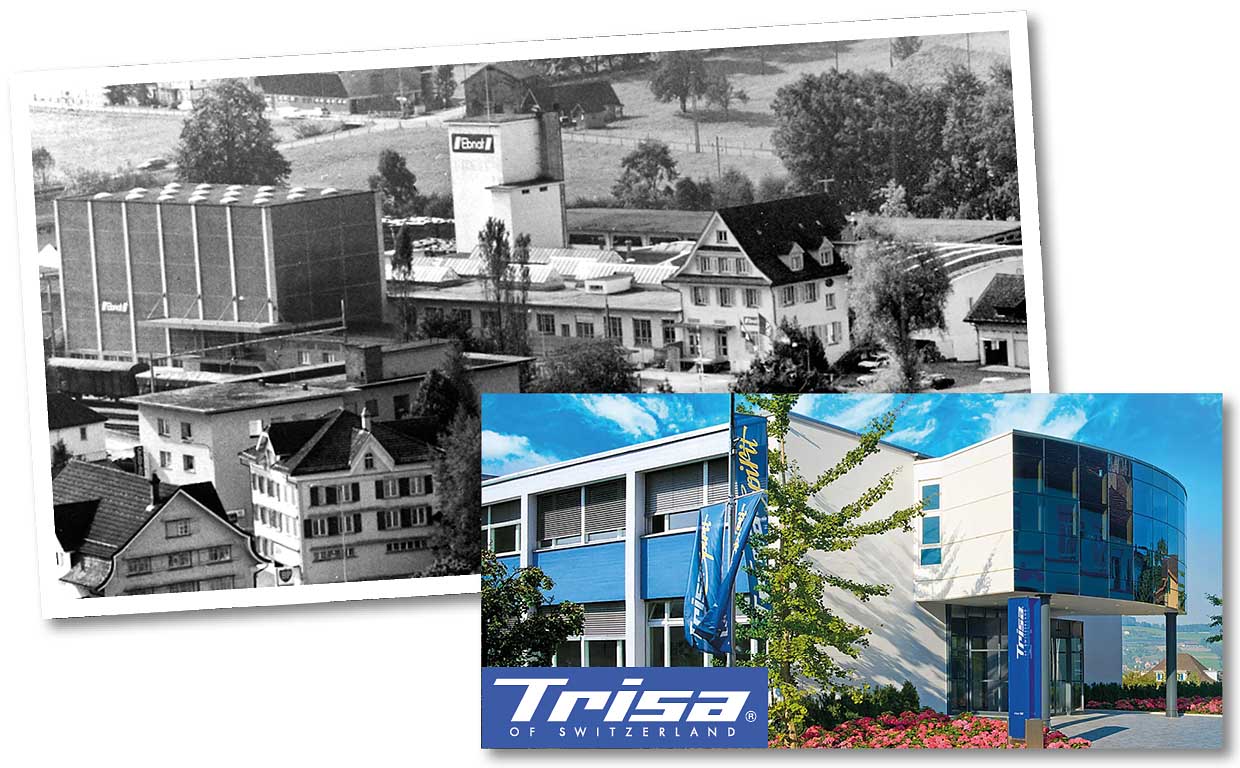

Ebnat entrepreneurs found Toggenburgische Holzwaren- und Bürstenfabrik AG. The business starts in a former embroidery building, employs two dozen people and is managed by Martin Flubacher.

1917

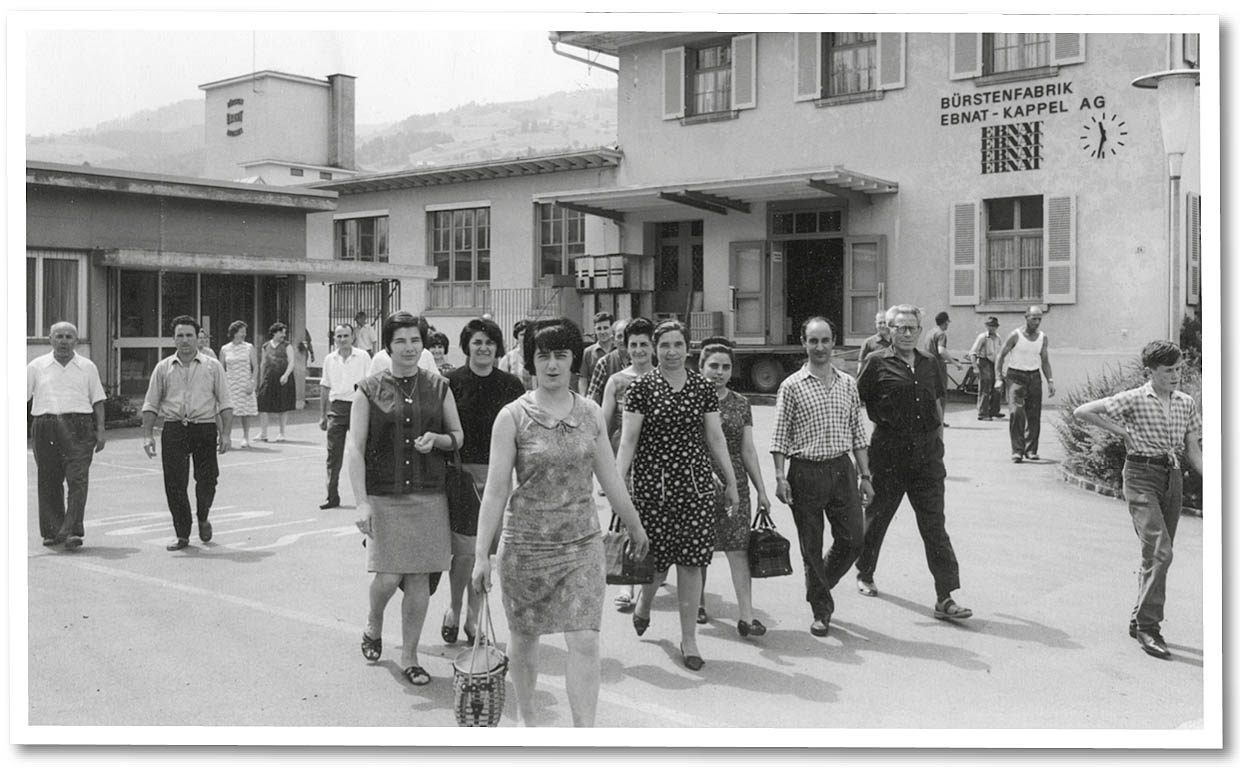

The brush factory with its more than 100 employees moves to a new building next to the Ebnat-Kappel railway station (current location).

The first Swiss street sweeper of the brush factory is used.

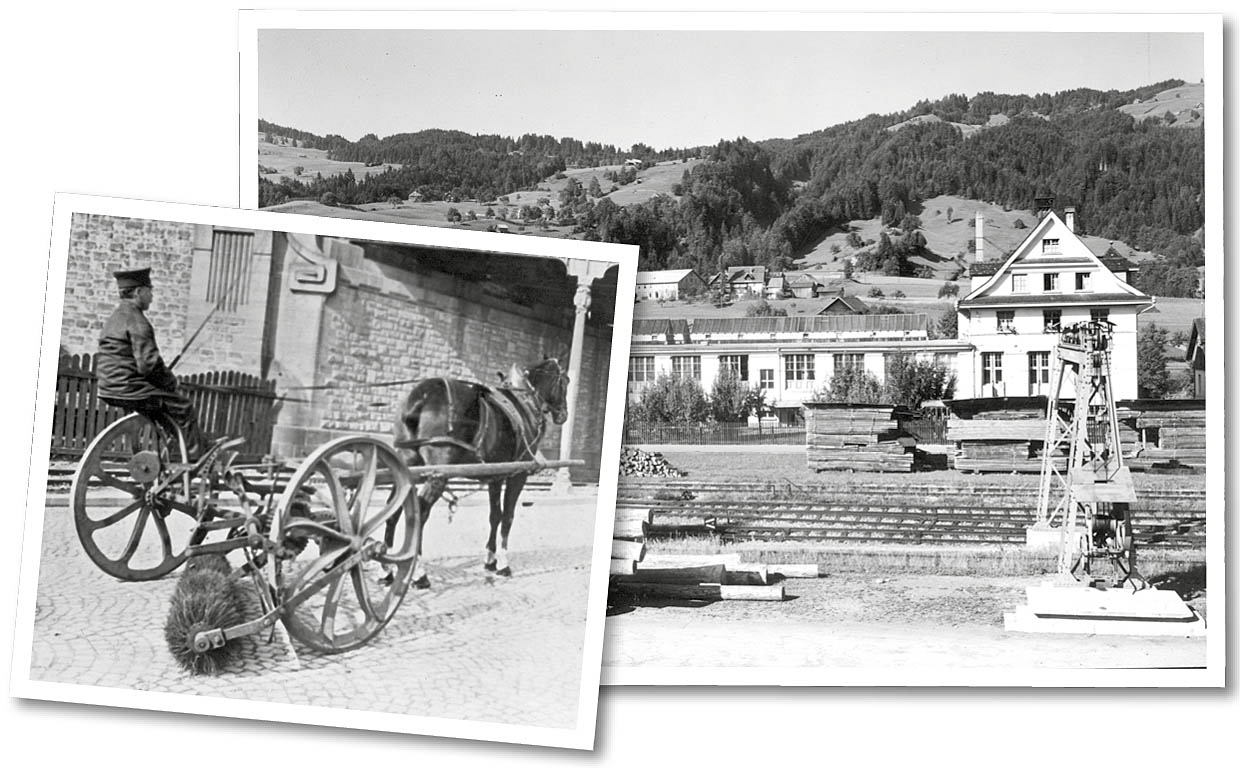

1923

Probate of Flubacher's company. Schweizerische Volksbank buys the company, dismisses the management, founds Bürstenfabrik Ebnat-Kappel AG and hires the German brush expert Otto Wissler.

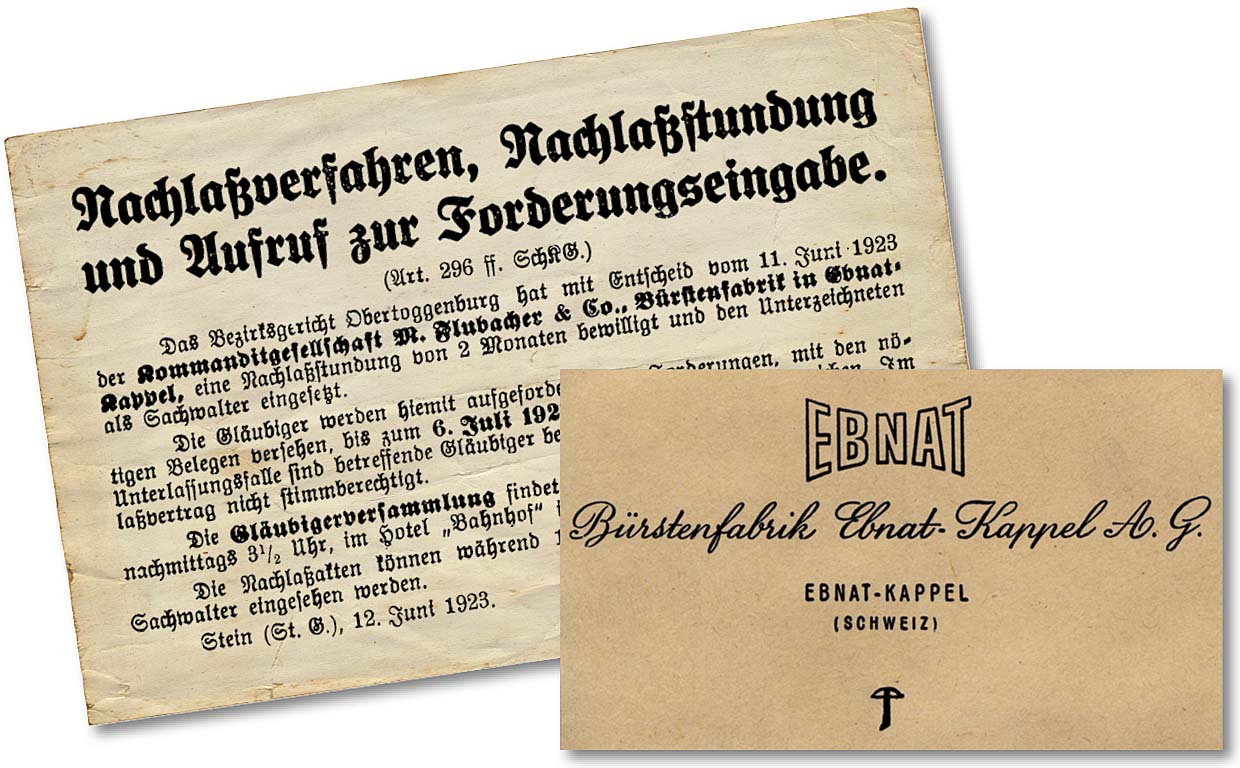

1925

In order to continue to employ the 70 staff members, Volksbank is now focusing on the commercial management of the company. The 31-year-old businessman Hermann Naef, who has made a name for himself with his push-button factory in Mogelsberg, is brought in as turnaround manager.

Patent for block brush «Matador»

1933

In 1931, the Swiss Intellectual Property Office granted the German inventor Leo Levy a patent for a toothbrush in which the bristles are anchored in a metal plate. This brush can be washed hot without the bristles falling out. Two years later, Levy fled to Switzerland to escape the Nazi regime and took a job at the brush factory in Ebnat-Kappel. This turns his idea into a product: the Implata toothbrush.

1939

The number of employees at the brush factory reaches 120 - a record! But the wage level has fallen. Minimum prices for brushes should help. While this is being discussed in the Federal Parliament, the Second World War breaks out, which soon brings maximum price regulations.

1944

The brush factory separates from Volksbank and becomes an independent public limited company. Over the next 20 years, the workforce at the brush factory grows to 200.

1946

"Bürsti" employs 300 people, partly in shifts. A factory expansion with the current silo building is realised.

1953

For company employees and external persons who cannot bathe at home, the brush factory is building two new baths and showers. The latter can use the facility Wed, Thu and Sat for a small fee.

1955

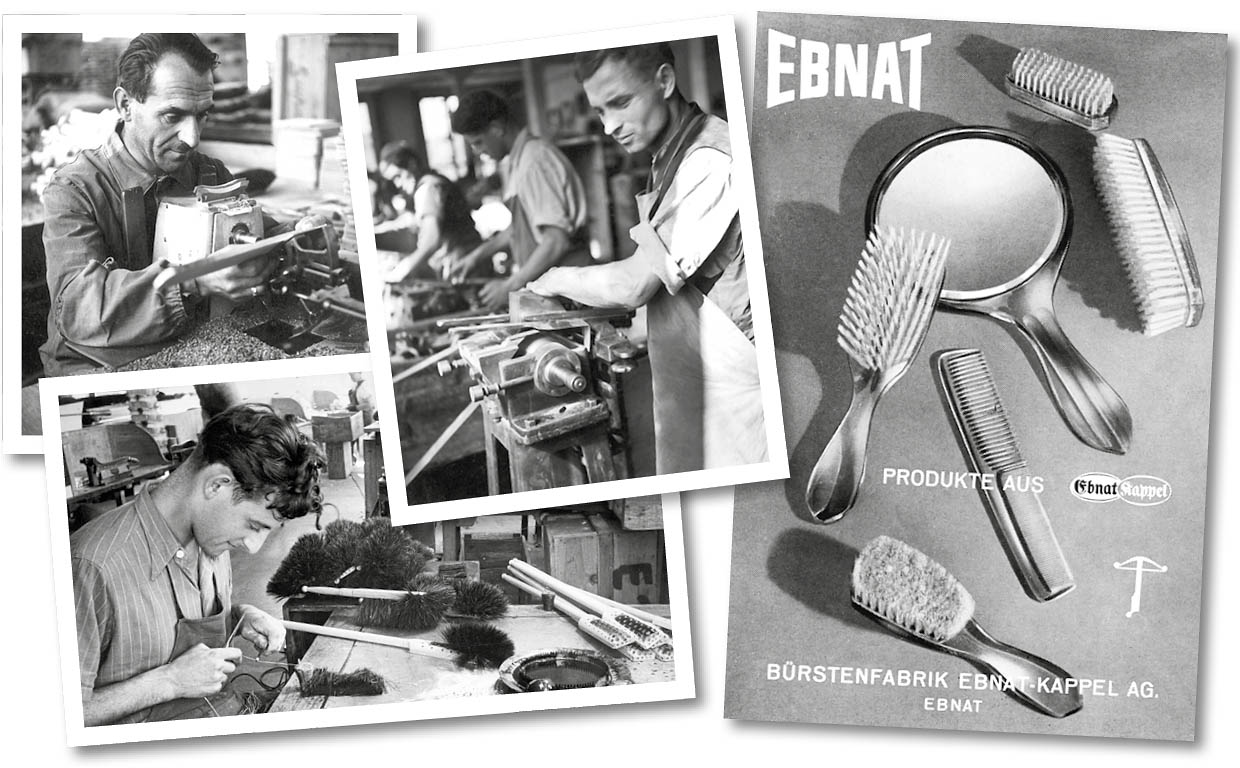

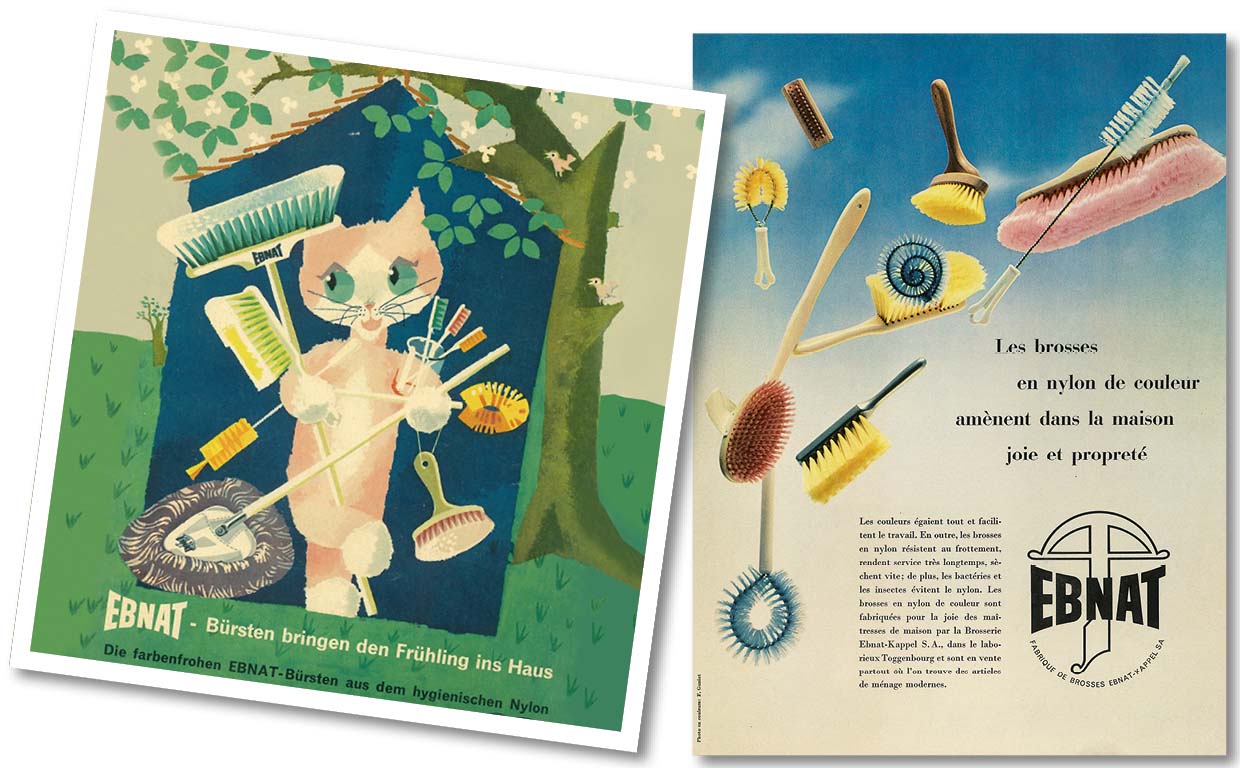

The brush factory Ebnat-Kappel AG brings brushes with nylon trimming on the market. This colourful novelty is considered particularly hygienic and durable.

1964

Following the construction of a new mechanical workshop and the establishment of its own plastic injection moulding shop, Ebnater Bürstenfabrik uses the first injection moulding machine (Netstal) for the production of brush bodies.

1977

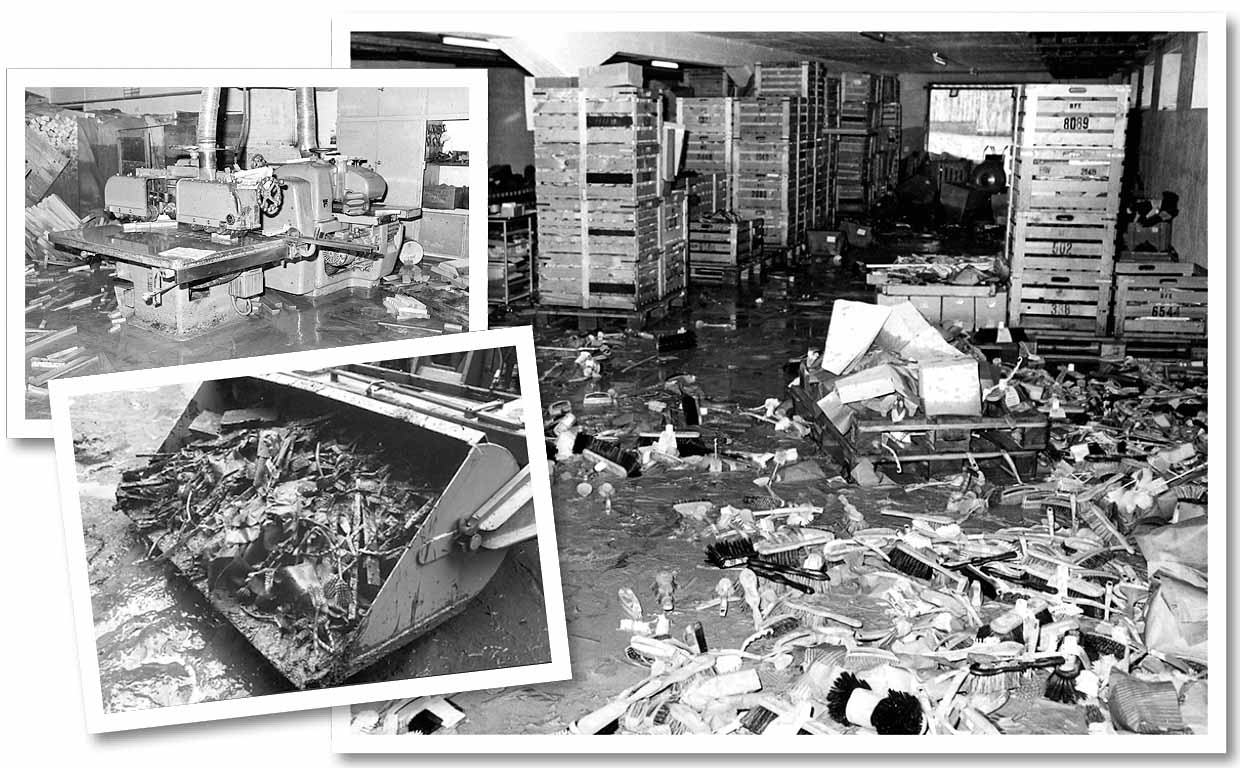

In August the Thur river floods the factory: In the cutting area, the machines are one metre under water.

Nonetheless, "Bürsti" can be pleased about new record results: Turnover 13.1 million CHF; gross profit CHF 1.2 million

1980

Production numbers continue to rise and storage space is becoming scarce. The construction of a high-bay warehouse is realised.

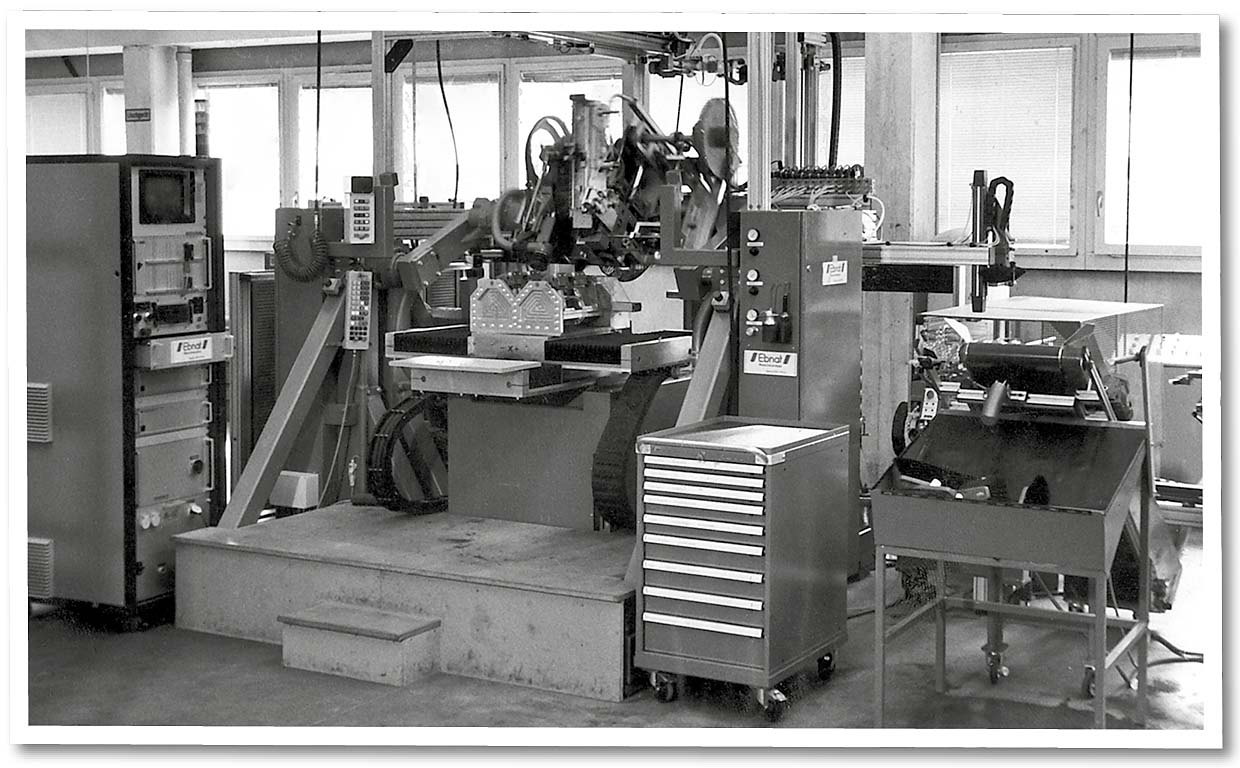

1984

The brush factory develops and builds a microprocessor-controlled punching machine. An absolute innovation in the industry!

1989

Integration of Bürstenfabrik Ebnat-Kappel AG as independent subsidiary in TRISA Holding.

1993

Production is being further increased: A new building for the toothbrush production and the thermoplastic injection department is erected.

1996

The brush factory receives the ISO certificate for its quality and environmental management system.

1997

Space is also becoming scarce outside of production: The office facilities are expanded to create more space for the sales, AVOR, marketing and product design staff.

2004

Within the TRISA Group, "Bürsti" becomes the competence centre for interdental and household brushes.

After 90 years of existence, it has 160 employees (including 13 apprentices), 6000 customers and 1000 articles. Around 80% of the turnover is generated in Switzerland, the rest in the export business to the EU, England, the USA, Canada, the Middle East, the Baltic States and Japan.

2008

For strategic orientation a major investment is being made in interdental production. Ebnat builds two lines for injected interdental brushes.

2013

Ground-breaking and start of construction for another major company expansion.

With two open days and an extensive entertainment programme, Bürstenfabrik Ebnat-Kappel AG celebrates its 99th anniversary.

2014

As of 1.1.2014, Bürstenfabrik Ebnat-Kappel AG will be renamed Ebnat AG.

In late autumn, the expansion of the production building, the construction of a cold storage hall and a new logistics platform, as well as the renovation of the old building are officially inaugurated.

2015

Michele Vela becomes new director of Ebnat AG and replaces Pius Thoma.

2016

In the in-house woodworking shop, a new cutting machine for wooden scantlings is put into operation.

2018

Ebnat AG was the first brush factory to set up industrial production of wooden toothbrushes and produces the first toothbrushes of the "new" generation from regional beech wood and bamboo. Ebnat also becomes a centre of excellence for wooden toothbrushes.

For thermoplastic injection moulding, two granulate silos are installed.

2020

A further expansion is being realised: The production building will be extended with a third level and an additional 2'500 m2 storey. In the spirit of sustainability, the new roof is optimally used to generate its own electricity with a PV system.